Green Duck Customs Presents:

The Definitive Guide to Premium Wooden Cutting Boards:

Science, Selection, and Stewardship

Why Wood remains the culinary standard for cutting boards

The cutting board serves as the foundational element of kitchen productivity—the critical interface between the chef and raw ingredients. Historically, wood has been the material of choice for centuries, a legacy that modern food science is now actively supporting and validating. High-quality wooden cutting boards, particularly those engineered with sophisticated end grain construction, represent a significant, long-term investment in kitchen safety, knife longevity, and overall culinary efficiency.

part i: The Science of Safety: Wood vs. Plastic

The Great Myth Debunked: Challenging the Plastic Orthodoxy

For many decades, a widely held, yet unsubstantiated, conventional wisdom asserted that plastic cutting boards were inherently safer than wood because of their non-porous nature.¹ This perception led many industry observers to treat plastic’s superiority as an article of faith.¹ However, the physical reality of plastic in a culinary environment undermines this assumption. Plastic surfaces quickly accumulate thousands of microscopic knife scars and indentations after just a few months of use.² These grooves function as reservoirs for bacteria, making the boards progressively more difficult to sanitize effectively, even when using aggressive cleaning agents like bleach or high-temperature dishwasher cycles.² Furthermore, as plastic boards become worn and scarred, they pose environmental and health concerns by potentially releasing microplastic particles into food.³

Sources:

(1) Cliver, D. O., & Ak, N. O. Cutting Boards of Plastic and Wood Contaminated Experimentally with Bacteria. Journal of Food Protection, University of Wisconsin–Madison.

(2) Ak, N. O., & Cliver, D. O. (1999). Decontamination of Plastic and Wooden Cutting Boards. Journal of Food Protection.

(3) Rochman, C. M. et al. (2015). The Ecological Impacts of Marine Debris. Ecology.

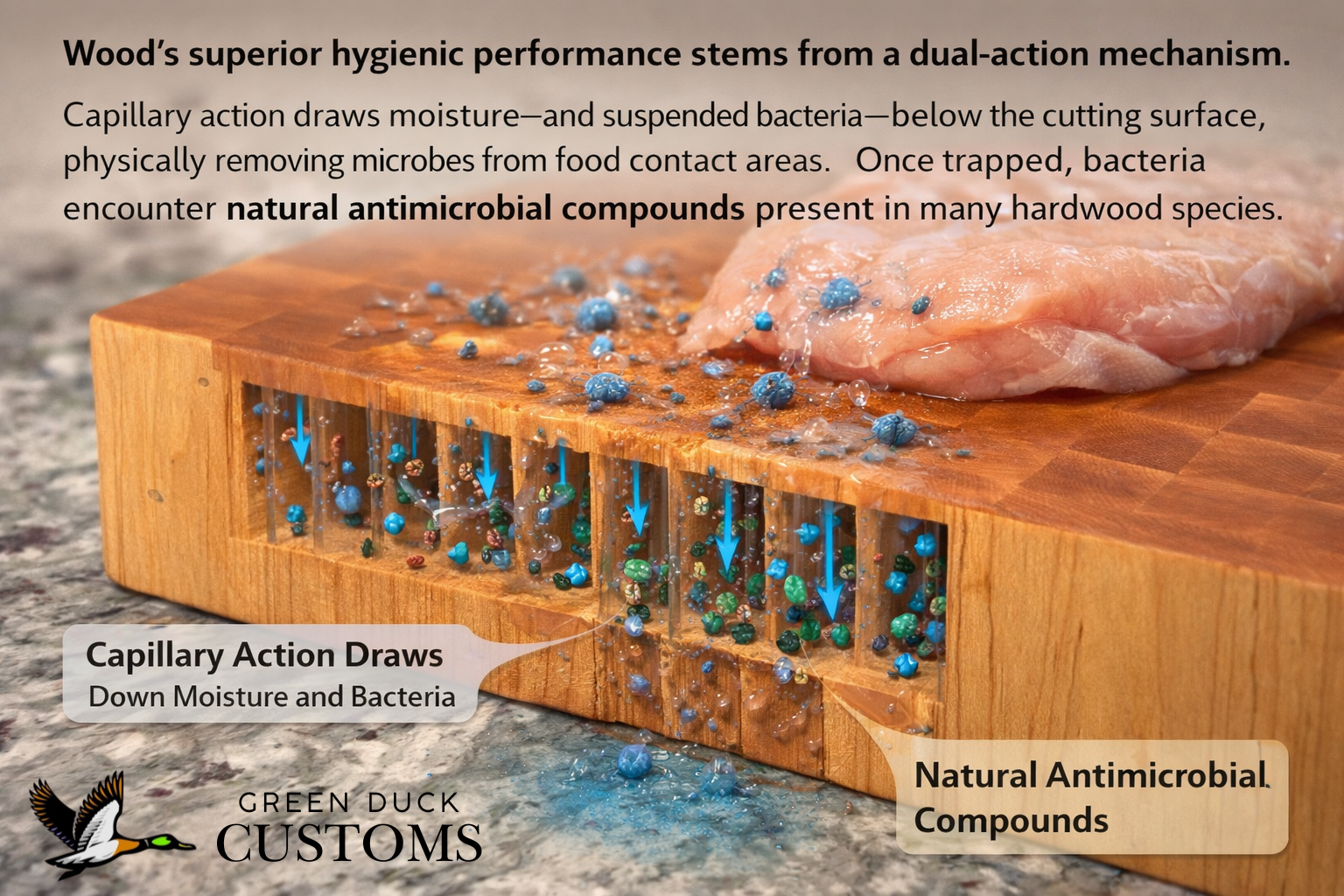

The Natural Advantage of Wood: Capillary Action and Antimicrobials

Wood’s superior hygienic performance stems from a dual-action mechanism. First, capillary action draws moisture—and suspended bacteria—below the cutting surface, physically removing microbes from food contact areas.² Second, once trapped, bacteria encounter natural antimicrobial compounds present in many hardwood species. Multiple studies have demonstrated that hardwoods such as maple inhibit bacterial survival.² Because bacteria cannot multiply within the wood structure, they die naturally.⁶ This combination of physical isolation and chemical inhibition makes wood more forgiving than plastic when minor sanitation lapses occur.¹

Sources:

(1) Cliver, D. O., & Ak, N. O. Cutting Boards of Plastic and Wood Contaminated Experimentally with Bacteria. Journal of Food Protection, University of Wisconsin–Madison.

(4) Cliver, D. O. (1994). Food Safety: Wooden Cutting Boards. Food Research Institute Briefings.

(5) United States Department of Agriculture. Kitchen Cutting Board Research Review.

GREEN DUCK CUSTOMS’ PROFESSIONAL KITCHEN CUTTING BOARD SET (PKCB)

Scientific Spotlight: The University of Wisconsin Studies (Cliver and Ak)

The most definitive challenge to the plastic orthodoxy came from the University of Wisconsin–Madison Food Research Institute. Food microbiologists Dean O. Cliver and Nese O. Ak initiated research intending to develop sanitization methods that would make wooden cutting boards nearly as safe as plastic. The resulting findings were unexpected: wooden cutting boards actively kill bacteria that survive on plastic surfaces.¹

In controlled studies, boards were deliberately inoculated with pathogens such as Salmonella and Listeria. Clean wooden blocks absorbed contaminated fluids within 3–10 minutes. At typical contamination levels (10³–10⁴ CFU), bacteria could not be recovered after absorption.⁴ Even under extreme contamination (≥10⁶ CFU), recoverable bacteria were reduced by at least 98%, and often more than 99.9%, within 12 hours at room temperature.⁴ These results fundamentally challenge the assumption that plastic cutting boards are inherently more sanitary than wood and revealed that former USDA recommendations favoring plastic were not supported by empirical evidence.⁵

Sources:

(1) Cliver, D. O., & Ak, N. O. Cutting Boards of Plastic and Wood Contaminated Experimentally with Bacteria. Journal of Food Protection, University of Wisconsin–Madison.

(4) Cliver, D. O. (1994). Food Safety: Wooden Cutting Boards. Food Research Institute Briefings.

(5) United States Department of Agriculture. Kitchen Cutting Board Research Review.

Best Practices for Preventing Cross-Contamination (USDA Guidance)

Despite wood’s passive safety advantages, safe food handling remains essential. Cross-contamination is a leading cause of foodborne illness.⁸ The USDA recommends a two-board system: one board dedicated exclusively to raw meat, poultry, and seafood, and a separate board for ready-to-eat foods such as produce and bread.⁹ Using distinct wood species or visual differences helps reinforce this habit.⁸

Sources:

(8) CDC. Cross-Contamination and Foodborne Illness.

(9) USDA Food Safety and Inspection Service. Cutting Boards and Food Safety.

part ii: Engineering the Surface: End Grain vs. Edge Grain Construction

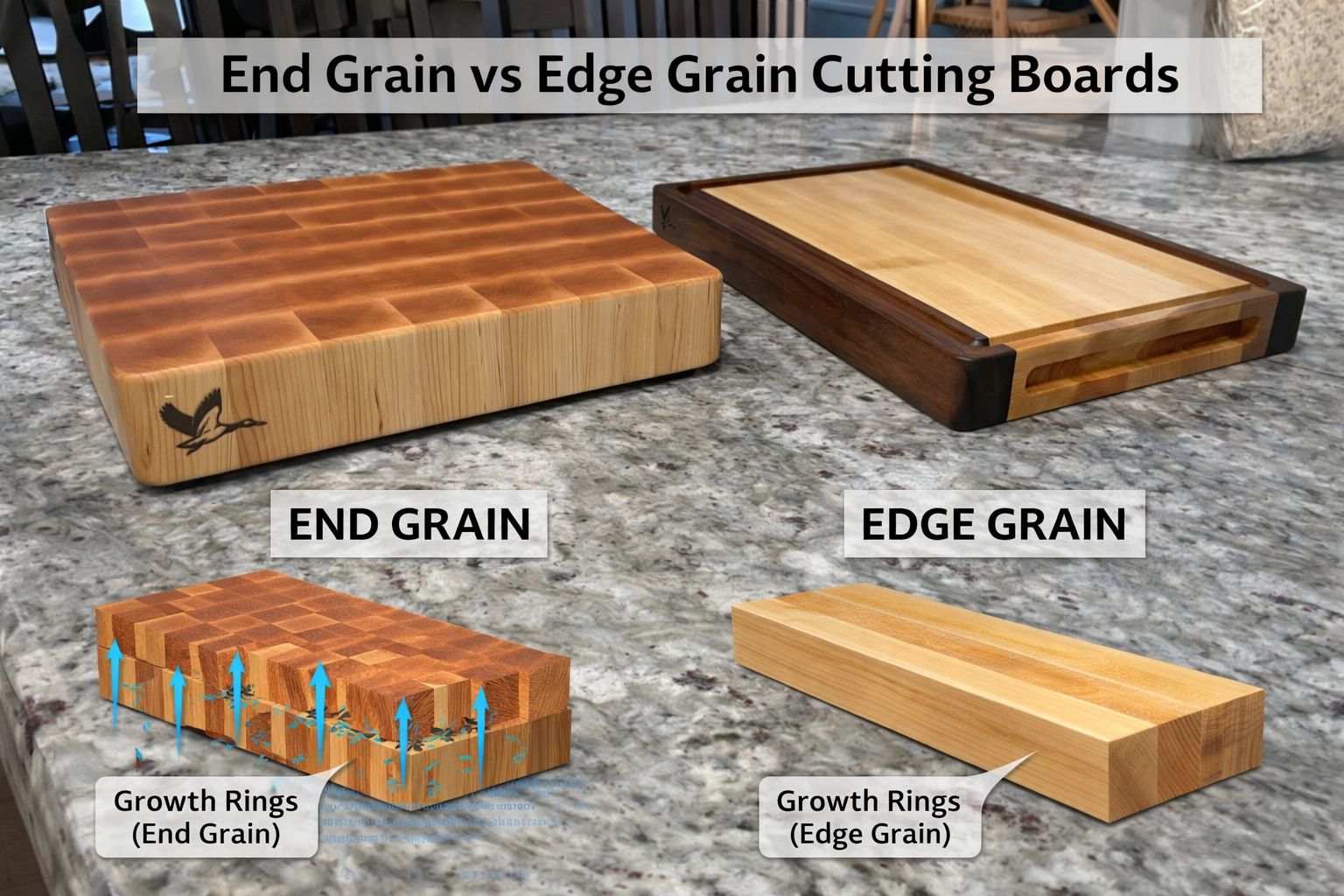

end vs edge grain defined

Edge Grain boards are constructed from long strips of wood glued side-by-side, exposing the side grain on the cutting surface.

End Grain boards are assembled from small wood blocks oriented so the ends of the fibers face upward, producing a checkerboard OR STAGGERED BRICK appearance. While checkerboard patterns are harder to craft, we make the majority of our boards this way because we believe it maximizes the aesthetic appeal of the board.

edge grain: the value workhorse

Edge grain boards provide excellent performance at a lower cost and with reduced maintenance. While not as knife-friendly as end grain, they remain significantly gentler on blades than plastic or face grain boards. Edge grain boards are often preferred for serrated knives or high-risk tasks.

the reduced maintenance attribute is significant- these boards do not require as much routine oiling and overall care as an edge grain board and will hold up better with less attention.

End Grain Mastery: The Premier Surface

End grain construction is widely regarded as the superior choice for high-performance kitchens.¹⁴ When a knife strikes an end grain board, the blade passes between vertical fibers rather than severing them, similar to cutting into a bundle of bristles.¹² This significantly preserves knife edges and reduces sharpening frequency.¹⁴

End grain boards also exhibit self-healing properties: fibers separate under the blade and then close back together, minimizing visible knife marks and reducing deep scarring that could harbor bacteria.¹² ¹⁶ These boards are heavier, more expensive, and require more diligent oiling due to their complex glue structure.¹⁸

(12) Hoadley, R. B. Understanding Wood. Taunton Press.

(14) Knife Steel Nerds. Cutting Board Materials and Edge Retention.

(16) Fine Woodworking Magazine. End Grain Cutting Board Construction.